FUSION 360 TUTORIAL PATCH PATCH

the class will focus on best practice and proper t spline patch topology to maximize.Įxtending Surface Edges | Fusion 360: Surfacing With The Patch Workspace

FUSION 360 TUTORIAL PATCH SOFTWARE

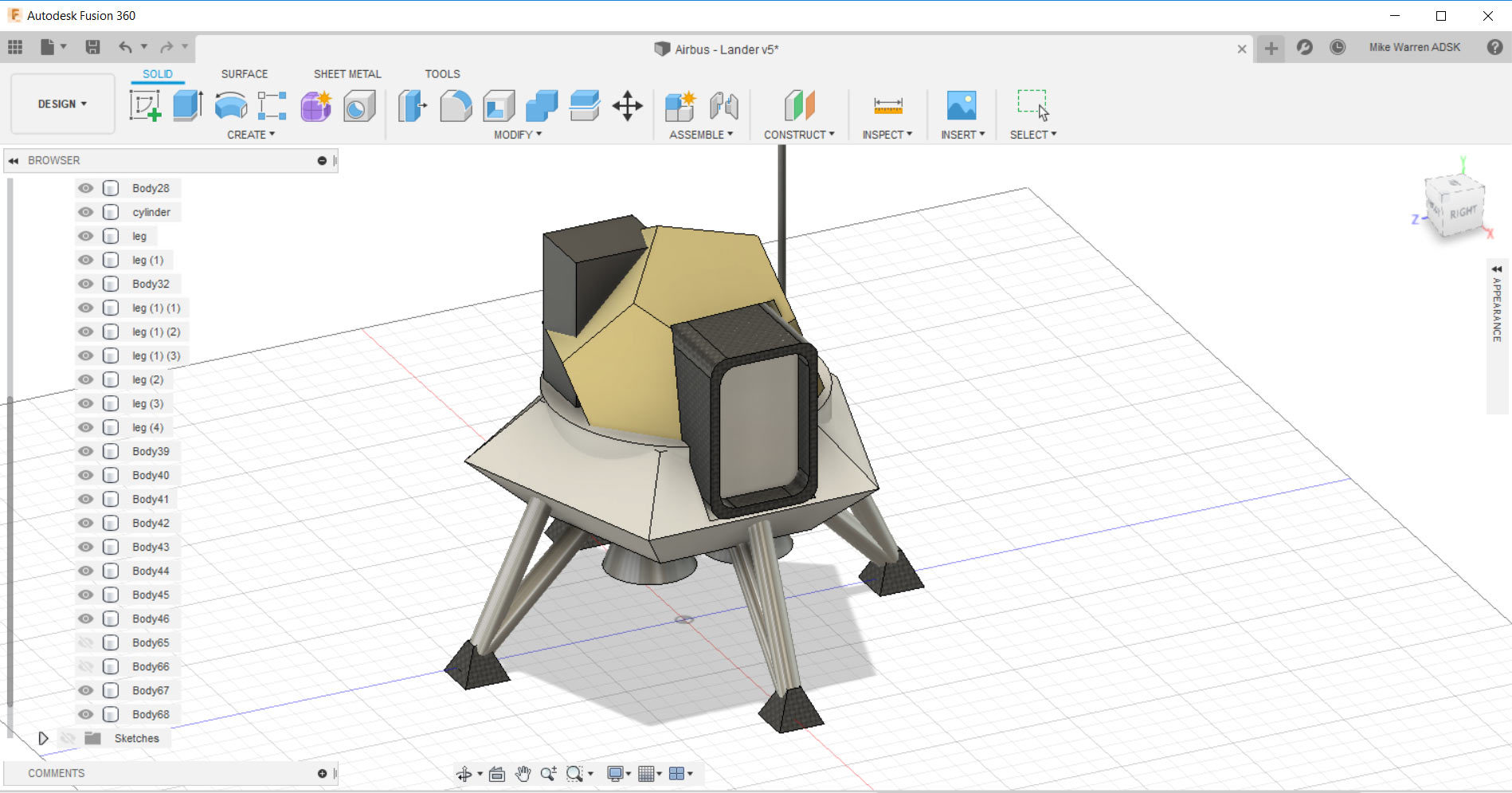

This class will demonstrate a workflow that uses the t splines module in fusion 360 software to create nurbs like surface patches utilizing sketches as a base start and sub d modeling and pair the generated boundary representations (breps) with solid modeling tools inside the parametric timeline environment. if you need help, if you find a new technique that you love, if you think you have a bug, let us know! we also love it when you post your tips, designs, videos, and general experience with the product and workflow. This sub is for any and all content related to autodesk autocad fusion 360.

FUSION 360 TUTORIAL PATCH HOW TO

make sure you bookmark this article! 目次 1 what is fusion360?2 advantages of fusion3602.1 file management in fusion3603 how to use fusion3603.1 surface modelling in the patch workspace3. i’ve added diagrams to make it even easier to understand. The first Operation will determine if the model will remain a single component or become an assembly.Practice Surfacing With The Patch Ii In Fusion 360Īn easy to understand explanation of how to use fusion360 in this article, i’ll explain how to use fusion360, a popular 3d cad software program. Use the Flange command to create the base flange feature. Expand this component to discover the sheet metal rule and bodies associated with this part.Īs more flange features are added to the design, you can decide if they will add to an existing part, or if they will become a new component. The browser now indicates that you are working in an assembly. Leave the Thickness as Side 1, but change Operation to New Component. Repeat the Flange command and select the profile interior as before. To compare the assembly workflow, click Undo as needed to remove the flange feature from the Timeline. You could continue to develop this design as a part. A warning appears, stating that the operation is not supported. Right-click Body1, and then select Create Components from Bodies. However, a limitation is imposed for sheet metal bodies, which prevents this action. In the Model workspace, you can normally convert bodies to components. In the browser, the part icon has changed to a sheet metal icon, and the sheet metal rule appears below the Document Settings. Set the Operation as New Body, and then click OK to create the base flange.

If you are designing an assembly, you should select New Component. If you are designing a single part, you can leave this setting. Since this is the first feature, the Operation type has defaulted to New Body. Be aware that this is using the material thickness value, and not the k-factor or neutral axis distance. In the dialog, this direction is shown as Side 1. The model has been extruded or thickened in the positive direction of the sketch plane. A preview of the base flange appears using the default sheet metal rule. The Flange dialog box appears, and you are prompted to select profiles. In this model, a sketch has been created for the base feature. The base flange type is one of the most commonly used in sheet metal parts. The Flange command is a multi-purpose tool used to create a variety of flange types. A base flange, created with the Flange command, is one of the most common features found in a sheet metal part.

0 kommentar(er)

0 kommentar(er)